Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Industry News ->

USES: brown corundum is made from high quality aluminum oxide powder, and brown corundum sand is refined and crystallized by electric melting, with high purity, good self-sharpness, acid and alkali corrosion resistance, high temperature resistance and stable thermal performance.The hardness of brown corundum is slightly higher than that of brown corundum, with slightly lower toughness, high purity, good self-sharpness, strong grinding ability, low calorific value, high efficiency, acid and alkali corrosion resistance, and high temperature and thermal stability.Brown corundum sand is used for grinding high carbon steel, high speed steel and stainless steel.Brown corundum segment sand can also be used for precision casting and high - grade refractory materials.

Section sand of brown corundum: 0-1mm, 1-3mm, 3-5mm, 5-8mm, 8-12mm

Physical and chemical indicators: Al2O3≥99%, Na2O≤0.5%, CaO ≤0.4%, magnetic substances ≤0.003%

Brown corundum powder: 180#-0, 200#-0, 320#-0

Physical and chemical indexes: Al2O3≥98.5%, Na2O≤0.5%, CaO ≤0.5%, magnetic substances ≤0.003%

Brown corundum is the most economical abrasive suitable for both dry and wet production processes, especially for the rough surface treatment of the workpiece, and the surface after treatment and more fine occasions.This sharp, angular synthetic material is second only to diamond in hardness and is often used where iron contamination is strictly required.It can be used to cut very hard materials or made into spheres to treat the workpiece of precise size to achieve extremely low roughness.Its dense, sharp, angular structure makes it the fastest cutting abrasive.Brown corundum is produced by electrofused high quality aluminate (alumina) to produce powder corundum and brown corundum.Its natural crystal structure makes it hard and fast to cut.At the same time, they are often used as raw materials for consolidation and coating of abrasives.Brown corundum can be used repeatedly in standard sandblasting equipment. The number of times of recycling is related to material grade and specific process.Scope of application: aviation industry, automobile industry, casting industry, semiconductor industry, etc.Aluminum and alloy products to deburr, remove pot dirt;Mold cleaning;Metal sandblasting before pretreatment;Dry and wet grinding;Precision optical refraction;Grinding of minerals, metals, glass and crystals;Glass carving and paint additives.Instructions: brown corundum is used for dry or wet sandblasting equipment with compressed air.Brown corundum has a very high hardness, wear out the poor quality equipment quickly.When using corundum, it is better not to use tungsten-carbon alloy spray gun, but to use boron or silicon-carbon alloy spray gun.

Brown fused alumina industrial alumina powder as raw material, the arc after cooling in integrated by more than 2000 degrees high temperature melting, after smashing plastic, magnetic separation to iron, screen is divided into a variety of particle size, dense texture, high hardness, granular form sharp corners, is suitable for manufacturing ceramic porcelain, resin consolidation abrasive and grinding, polishing, sandblasting, precision casting, precision casting special corundum), etc., can also be used for manufacturing high-grade refractory materials, code-named "WA" international general standards, national standards are consistent, most for export, supply domestic users also have a certain amount.Product size according to international standards and national standards production, according to user requirements for particle size processing.The general particle size is F4~F320, and the chemical composition varies according to the particle size.The outstanding feature is that the crystal size is small impact resistance, if the grinding machine is used to crush, the particles are mostly spherical particles, the surface is dry and clean, easy to bond with the agent.

Relevant Product Display

Aluminum silicate fiber rope

Aluminum silicate fiber rope

Outside furnace refining system castable

Outside furnace refining system castable

High temperature anti - corrosive spray paint PT-160

High temperature anti - corrosive spray paint PT-160

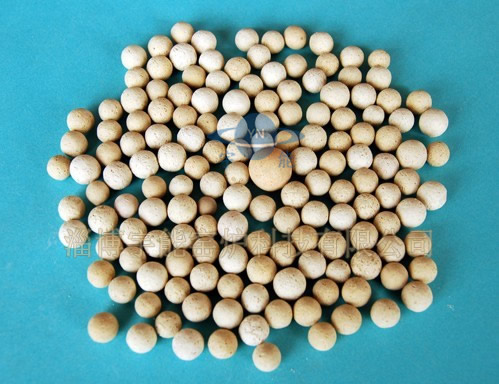

Regenerative ball

Regenerative ball

Relevant information

Hotline