Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Industry News ->

1. Welding 12 channel steel into &ldquo on the chimney ash platform;Well & throughout;There is a square hole about 2m left in the middle (preferably a round hole with a diameter of 2.5m, which can be used for feeding). A 50mm thick foot board is laid in addition to the hole. Four lifting rings of 20 are welded at the four corners (edges) of the hole.

2. Install 4 pulleys at a height of about 1m on the operating platform to operate the lifting and lifting of the platform. When lining with a height of about 1.5m is built each time, the pulleys can be pulled to lift the platform to the construction surface (once every 1.5m).

3, because of the small chimneys on the next big, platform gradually rise will be gradually reduced, so the type in the channel to channel steel tube closed square head, square tube can be set into the pick of telescopic stem (ram can design according to the channel steel square tube diameter size) so that the construction platform before ascending the ram can be a bit indentation, and dressing table, platform in place around the platform can be picked out, falls on build by laying bricks or stones good lining masonry (when can not meet the requirements, can be channel steel part resection), improve operation platform, and repeatedly repeatedly so construction).

4. Construction sequence: lifting operation platform →Cleaning concrete surface slurry debris →Brush inner wall acid proof coating degree 2 →Lining acid-resistant brick →Fill insulation material (when 10 m, 20 m „& bdquo;When the cantilever of node is used, the pre-embedded steel bar of node is dug out in advance, and then the horizontal distribution of the steel bar is bound according to the requirements of the drawing, and then the cantilever concrete of node is cast by supporting mold.

5. The construction personnel open the hoist on the operating platform, and the transport switch is used for feeding. The construction is carried out in two shifts (24 hours) continuously.

6, personnel up and down method: personnel up and down, the material transport is using the concrete chimney construction hoist to lift the hanging basket, lifting the hanging basket no track rope can be equipped with two 16 wire rope track rope, between the hanging basket and the track rope set two safety locks, in order to prevent the hoisting machine and wire rope accident.

Relevant Product Display

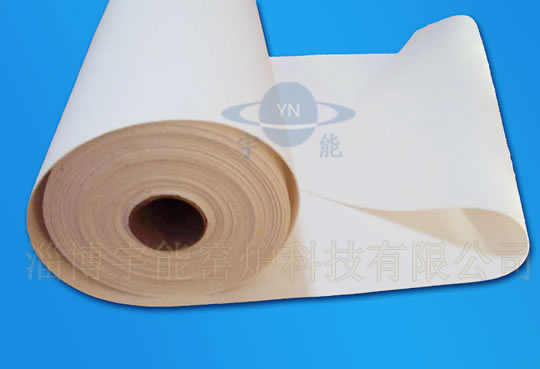

Ceramic fiber paper

Ceramic fiber paper

Ordinary ceramic fiberboard

Ordinary ceramic fiberboard

Lightweight insulating castable YL-14Q

Lightweight insulating castable YL-14Q

High strength refractory castable D-13

High strength refractory castable D-13

Relevant information

Hotline