Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Industry News ->

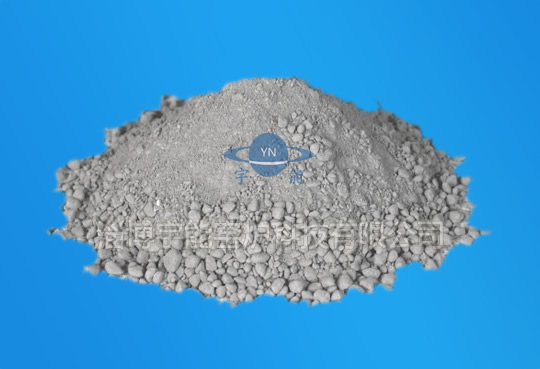

Corundum wear-resistant refractory plastic

Features:

Belongs to the high temperature wear-resisting refractory field.The raw materials are composed of high-alumina homogenized materials, alumina micro powder, silica micro powder, clay, phosphoric acid, aluminum dihydrogen phosphate solution and pure calcium aluminate cement. The homogenized materials are: Al2O3 content is 70 ~ 90%, volume density is 2.9 ~ 3.5 cm - 3 g ".It is characterized by the use of low water absorption rate, low porosity rate and high uniformity of synthetic homogeneous material instead of the traditional high absorption rate, high porosity rate and uniformity of sintered alumina clinker natural raw material or corundum composite raw material system, the production of homogeneous corundum high strength wear-resistant plastic.

Construction technology:

This material adopts ramming construction technology, which is suitable for the parts with thin thickness such as water wall in furnace.The wear-resistant layer after construction has very high strength and wear resistance, different from the pouring material, but the plastic does not need to support the mold, direct use of daub, ramming construction method.The material of the invention has good construction performance, high intensity and good abrasion resistance, and has the best field use effect, which is conducive to extending the service life of furnace lining and improving the utilization efficiency of high temperature furnace.Applicable area:

It is mainly used in the dense phase zone of furnace chamber and steam - cooled cyclone separator.The wear-resisting refractory material in this area is designed as a single-layer ramming structure, fixed with wear-resisting pin. Its design thickness is relatively thin, generally about 55mm, and it is laid directly on the construction surface.

Relevant Product Display

Aluminum silicate fiber profile member

Aluminum silicate fiber profile member

[furnace castable] artesian/slag resistance/mullite

[furnace castable] artesian/slag resistance/mullite

Cupola melting strip castable

Cupola melting strip castable

High strength refractory castable HF/130/135/160

High strength refractory castable HF/130/135/160

Relevant information

Hotline