Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Industry News ->

Unshaped refractory precast block, which is mainly made of refractory castable and refractory plastic. It is classified into castable precast block and plastic prefabricated block; aluminum aluminate, water glass, phosphoric acid and aluminum phosphate, and clay are concluded. And pre-formed blocks of low-iron and other jointing agents; according to the aggregate types, they are divided into high-aluminum, clay, siliceous and corundum prefabricated blocks; according to the molding method, they are divided into sensation molding, shock pressure molding and beating molding precast blocks; The mass of the prefabricated block is tens of kilograms to several tons, so it is divided into heavy, medium and micro precast blocks; the prefabricated blocks are equipped with steel bars and anchors, which are divided into conventional precast blocks, steel precast blocks and anchor prefabricated blocks. Wait.

In industrial furnaces and warming facilities, the prefabricated block building furnace can be used to realize machined lifting, saving people's effort, shortening the construction period and mobilizing the blast furnace homework rate. The history of hot-fired kiln such as blast furnace, hot blast furnace, blast furnace, electric furnace top, mirror iron ore powder roasting shaft furnace and pellet baking furnace is used in the country. So far, the precast block is in the tapping tank, electric furnace top and roasting. The furnace is still in-depth use and exerts greater utility. In recent years, in the iron sump and the slag ditch of the medium and micro blast furnaces, the refractory castable prefabricated block lining has been cited, and good results have been obtained. The prefabricated block is factory-produced and shipped after low temperature treatment. Therefore, the lining speed is fast, it can be used without baking, and the furnace age is long, which is the key development trend in the future. It should be issued, and the materials such as refractory castables and refractory plastics can be used as prefabricated blocks. Because the production premise is better than the on-site construction, the function is also mobilized, and the above-mentioned related functions can be generally seen.

Nos. 1 and 2 are CA-50 steel and phosphoric acid clay castables, the aggregate is 70% clay clinker particles less than 10mm, and the high aluminum powder less than 0.09mm is 15% and 30%, CA-50 Steel is 15% and 2.5% respectively. The former is added with a decoction and the amount of water is 10%. The latter uses a purity of 42.5% phosphoric acid as a binder, the amount of 13%; Nos. 3 and 4 are water glass aluminum-magnesium castable precast blocks, the aggregate and powder are first-grade bauxite clinker, less than 8mm bone The dosage is 60%, the powder is 30% and 26%, the brick magnesia powder is 10%, the number of touch is 2.8, the density is 1.32g · the water glass is 9%, the latter is 4%. A graphite; serial numbers 5 and 6 are low-steel and ultra-low steel high-aluminum castables prefabricated blocks, respectively. The shape of the preform, which is important in the shape of a rectangle, a long line, an arch, and a ring, are all special-shaped articles. Function of refractory castable prefabricated block No. 123456 Chemical composition /%Al2O3SiO2Fe2O348411.256351.1678(MgO) 749(MgO)3(C)70151.6(CaO)64280.9(CaO) Pressure resistance /Mpa110°C1000°C1600°C2520342230422830134202530283860303442 High temperature bending strength /Mpa after burning line change /%1400 °C 1400 °C1.0 -0.201.2 +0.421.2 -0.12 -0.321.6 +0.891.7 0.98 refractoriness / °C apparent porosity /% bulk density / g · cm-3> 167017-2.241710163.321710212.481770182.601790 2.541790 2.60 The block and proportion of the precast block should be determined according to the size of the blast furnace and the thickness of the lining, try to reduce the specifications, save the plate, facilitate supervision and construction; prefabricated block for hoisting the furnace, single It is better to use 1~3t. The prefabricated block for manpower transportation and furnace construction shall have a single weight of not more than 30kg; the proportion, width and thickness of the precast block shall be 116mm and 68mm respectively, and the appropriate difference shall be elected. Block ratio. The width of the top of the furnace block depends on the length of the furnace and must not be less than 300mm. The height of the furnace wall precast block should be no more than 400mm. The width of the two prefabricated blocks is 3~8mm. When there is a hole in the precast block, the tire touch should have a slope of 1%~2%, and should be easily demolished; the heavy prefabricated block should be equipped with a lifting ring, the apex of which should be far away from the damp surface, the spacing should be greater than 200mm, and the thickness should be buried. 100~200mm. As the weight of the precast block increases, the radius of the ring reinforcement also increases.

Relevant Product Display

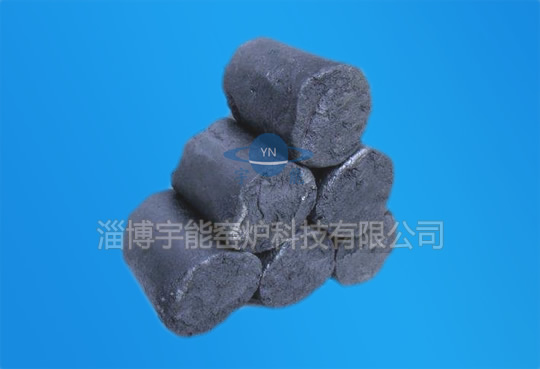

Anhydrous stemming

Anhydrous stemming

Aluminum silicate fiber cotton, shake silk cotton

Aluminum silicate fiber cotton, shake silk cotton

LT-4C Series of lightweight heat insulating lining castings

LT-4C Series of lightweight heat insulating lining castings

Ceramic fiber shaped structure

Ceramic fiber shaped structure

Relevant information

Hotline