Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

One-stop solution for building a large-scale power plant circulating fluidized bed boiler

Ultra-durable anti-erosion technology + fine selection of materials + long-term research and development test

Let us solve the problem

Home -> Product -> Refractory bricks ->

Phosphate wear-resisting brick

Hotline:+8613864463333

Technical parameters of phosphate wear-resistant brick are as follows: Items Brand and indicator P PA AL2O3(%)≥ 75 77 pressive strength,MPa≥ 60 62 volume density(g/cm3)≥ 2.65 2.7 0.2MPaStarting temperature of softening under loadRUL°C≥ 1350 1300 refractoriness(°C) 1770 1700 Phosphate wear-resistant bricks are mainly used as linings in high temperature parts of cement rotary kiln.It is suitable for rotary kiln firing belt, transition belt, cooling belt, cooling machine and other parts of high temperature zone of cement kiln, cement rotary kiln mouth, kiln tail and cooling belt, cooling machine and high temperature zone of cement kiln.When phosphate wear-resistant bricks are used in rotary kilns with kiln diameter larger than 4 meters, arch frame method (masonry machine) should be adopted. Phosphate wear-resistant storage: although phosphate wear-resistant better than magnesium brick, but also pay attention to moisture when storage. Instructions for use of phosphate wear-resistant bricks: The preparation of phosphate wear-resistant brick masonry mortar must be done before use: Phosphate wear-resisting brick special matching fire mud should be put in the special warehouse against rain and moisture, so as not to be affected by moisture and agglomerate;Special apparatus should be used to make the red fire mud of silicon moo and it should be cleaned in time.To modulate silicon mo red fire mud to use drinking water, the amount of water to be weighed accurately, harmonic to be even, with the adjustment with use;If the manufacturer supply is phosphate - bound cement, can be used directly.If the cement is found to have been solidified or hardened, do not mix it with water arbitrarily.Because the phosphate cement is corrosive, it should not be in direct contact with the metal shell.Measuring longitudinal and circumferential datum lines; Precautions for phosphate wear-resistant brick laying: Mallet or rubber mallet shall be used when laying bricks. Hammer shall not be used. Brick in place with a mallet after matter, squeeze out excess sludge, ensure the brick surface between solid brick (make sure the seam 1 mm or less), between mud brick and tile full (fire mud plumpness should reach more than 95%, it is forbidden to appear brick big head no mortar, small head with mortar, if you have this kind of situation, should be dismantled build by laying bricks or stones), surface brick seam jointing to have virgin pulp, but want to shave their surplus mud brick lining surface in time; In the course of laying, check the flatness of each ring and axial direction strictly according to the laid datum. The longitudinal joints should be in the same plane with the kiln axis, and the annular joints should be parallel to each other and perpendicular to the kiln axis.When the kiln cylinder is deformed, it should be straightened with steel plate or mud in time. Bricks in rotary kilns should be built with staggered joints.The brick surface is completely attached to the cylinder body to ensure that the brick ring is concentric with the kiln cylinder body.Masonry shall strive to avoid the occurrence of common problems such as dislocation, inclination, uneven ash joints, slope climbing, separation from the middle, reunion, joint opening, cavity opening and slurry mixing.

Zibo Yuneng Kiln Technology Co.,Ltd. is the professional Phosphate wear-resisting brick manufacturer in Shandong。Our company Phosphate wear-resisting brick sincerely obtains the prestige,rewards our customers with the preferential price of Phosphate wear-resisting brick and warm service。Our main products:refractory castable,high strength castable,alumina silicate fiber module,alumina silicate felt,alumina silicate fiber blanket,alumina silicate cotton,etc。The products sell well in dozens of metallurgical,chemical and electric power enterprises all over the country and are well received by users。The company's unique production process,quality management and testing equipment to ensure product quality and stability,has a high-quality staff and professional and technical personnel,according to the different requirements of users,the development and design of a variety of new refractory materials。To know the latest Phosphate wear-resisting brick price can be posted on our website https://www.zbyuneng.cn,we will contact you within 24 hours,Tel: 13864463333 Manager Sun。

Relevant Product Display

Wet spray feed series

Wet spray feed series

High alumina ramming castable PA-852

High alumina ramming castable PA-852

Ladle castable for electric furnace

Ladle castable for electric furnace

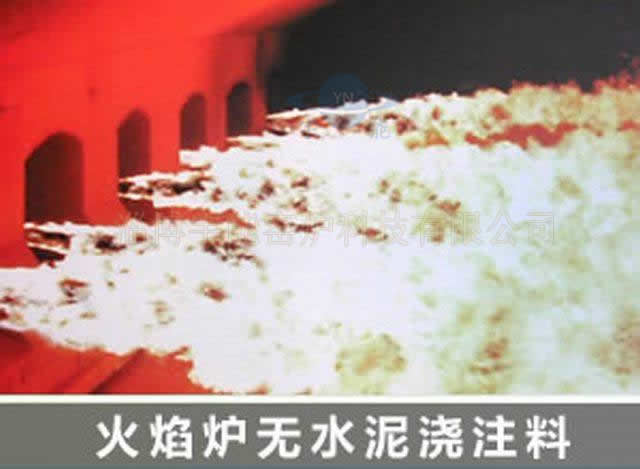

Castable for flame furnace systems

Castable for flame furnace systems

Relevant information

Hotline