Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

Kiln mouth refractory lining is the weak link of kiln lining, especially the front kiln mouth refractory lining, the service temperature is about 1100℃, need to withstand rapid cooling, hot gas shock, high temperature cement clinker wear and high temperature harmful gas alkali corrosion, the service conditions are very harsh.Lining damage is mainly: cracking, peeling and abrasion, so the requirement of refractories must have good thermal shock resistance, wear resistance and alkali resistance.

When the shell body of rotary kiln mouth does not deform, it can be built with high-alumina brick, spinel brick and magnesia chrome brick which can resist flaking.However, the deformation of the cylinder body is common, so casting with refractory castable, steel shell on the welding riveting nails, castable mixed with steel fiber reinforced refractory castable, according to the rules of construction and baking, to meet the needs of kiln mouth cylinder lining production.

In foreign countries, steel fiber reinforced refractory castable made of corundum and high alumina is widely used on the front of cement kiln, and its service life is up to 2~8.Castable has high aluminum content and high strength.Therefore, poor thermal shock resistance, easy cracking and peeling, reduce the service life.Production practice shows that steel fiber reinforced high alumina refractory castable has better effect than steel jade castable.

Relevant Product Display

High alkali resistant refractory castable GT-13NL

High alkali resistant refractory castable GT-13NL

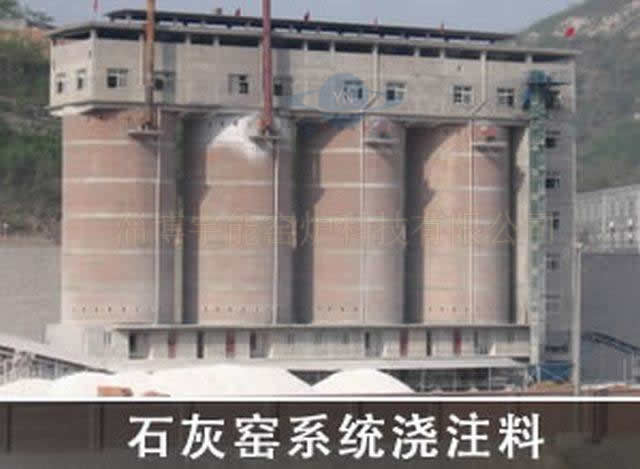

Lime kiln system castable

Lime kiln system castable

Ceramic fibre tape

Ceramic fibre tape

Corundum wear-resistant refractory plastic

Corundum wear-resistant refractory plastic

Relevant information

Hotline