Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

The circulating fluidized bed boiler is the national “seventy-five” project, “<;85” promotion project. The boiler has strong adaptability to coal quality, and can be used for lean coal, coal gangue and coal slag. The number of coal powder circulation is high, the burning rate is 98%, the thermal efficiency is high, the desulfurization effect is good, and the environmental pollution is small. It is an ideal supply. Steam, heating and power generation equipment.

The new boiler has high fluidization speed of coal-fired particles up to 5 m/s and can be as high as 21 m/s locally. It has strong scouring and wear on lining refractories at high temperature, plus the chemistry of impurities and lining materials in pulverized coal. The reaction and frequent heat exchange lead to the erosion, wear, spalling and collapse of the original refractory lining, which has to be frequently shut down for maintenance (usually 3 to 4 months), which seriously affects the normal operation and production of the boiler. Therefore, the development of new wear-resistant castables for circulating fluidized bed boilers to adapt to the promotion and application of new boilers is of great significance.

Circulating fluidized bed boilers are strongly affected by high-concentration, high-speed, turbulent fly ash particles at high temperatures, scouring, abrasion, and high temperature thermal stress and chemical attack, which seriously affect the service life of the boiler. To this end, refractory manufacturers are constantly researching various boiler lining series refractories suitable for their harsh working conditions, especially to meet the technical requirements of high strength, high wear resistance, high corrosion resistance and good thermal shock stability. Lined with refractory material. Refractory materials for lining of circulating fluidized bed boilers have gone through several stages: the first stage is refractory material for shaped products; the second stage is clay combined with castable; the third stage is phosphoric acid, polymerized phosphate, water glass, pure Aluminium aluminate cement or the like is a high alumina refractory castable of a binder. Although the wear resistance and refractory materials of the third stage are improved compared with the former two kinds of performances, due to the high CaO content in the binder, the high aluminum raw materials have many impurity components, and the construction performance is difficult to ensure, resulting in refractory stomata at high temperature. The rate is high, the strength is low, and the wear resistance is also poor. The fourth stage is based on the above materials. The corundum series wear-resistant castables (vibration castables and self-flowing) with low cement, ultra-low cement and no cement are successfully developed. Castable).

In the mid-1990s, our company began to develop wear-resistant refractory castables for circulating fluidized bed boilers, including vibrating castables and self-flowing castables.

The vibrating castable is mainly composed of low cement castable. The low cement castable is a castable developed on the basis of cement combined castable and clay combined with castable. It is often referred to as “high-tech pouring” at home and abroad. "," high-density castables" and "high-performance castables" and so on. In terms of ingredients, low cement castables are similar to cement combined castables and clay combined castables. They are composed of refractory aggregates, refractory powders and binders, but consist of refractory fines and binders. In the matrix, the ultrafine powder (particle size <1um) is used to replace part of the cement or the combined clay, and a small amount of dispersing agent is added to uniformly disperse the ultrafine powder between the aggregate particles and fill in the submicron-sized voids. Thereby forming a uniform and dense tissue structure. The key to low cement castables is the introduction of ultrafine powder and dispersion technology, which greatly increases the compactness of castables, and its main properties such as refractoriness, strength, wear resistance and thermal shock resistance are greatly improved.

The self-flowing castable is a high-tech new product developed on the basis of the vibrating castable according to the solid fluid theory. It is a new type of refractory material with a dense and uniform structure without vibration. The self-flowing castable has the following characteristics: the slurry has high thixotropy, can be self-flowing, degassing, self-leveling and compacting without vibration equipment during construction, saving labor and time-saving efficiency; and self-flowing castable mainly adopting composite ultrafine powder The combination of agglomeration reduces the content of CaO, thus overcoming the weakness of CaO dehydration, greatly increasing the compactness of the castable, and its main properties such as refractoriness, strength, wear resistance and thermal shock resistance. Greatly improved, meeting or exceeding the boiler lining material standards proposed by the famous circulating fluidized bed boiler design and manufacturer at home and abroad.

The wear-resistant refractory self-flowing castable developed by our company has excellent performance, high strength, good thermal shock resistance, small change in re-firing line, anti-scouring in use, corrosion resistance, no cracking, no peeling, and good volume stability.

Relevant Product Display

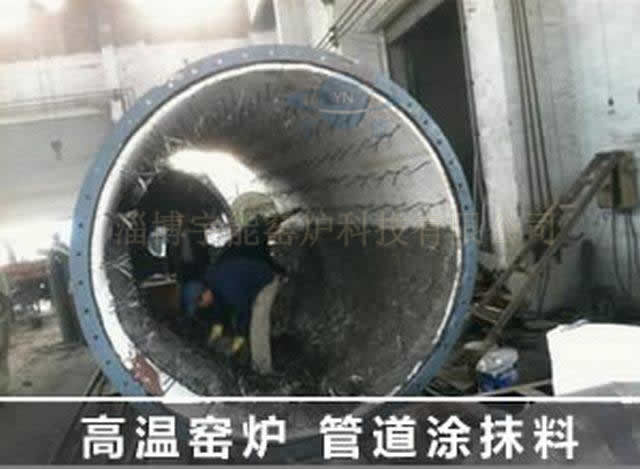

Super light insulation coating for high temperature kilns and pipes

Super light insulation coating for high temperature kilns and pipes

New slab corundum castable GC-18

New slab corundum castable GC-18

Refractory plastic series

Refractory plastic series

Quartz dry rammer

Quartz dry rammer

Relevant information

Hotline