Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Industry News ->

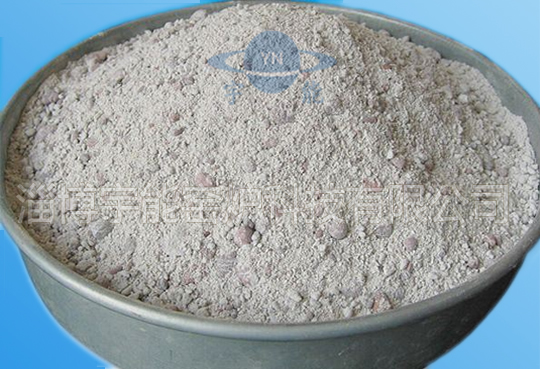

Refractory castables are basic castables that cannot be short of high temperature skill industries. The development of the key pillar industries of the people's finance such as hardware industry, pig iron industry, non-ferrous metallurgy industry, machine industry, chemical industry and modern high-tech industry (rocket, thermonuclear lining reactor) are inseparable from the development of refractory castable industry. . The quality and functional properties of refractory castables not only directly affect the quality of products, production costs and financial benefits of refractory castable users, but sometimes affect production and human safety. The development of the refractory castable industry has become one of the key prerequisites for the development of the people's finance.

The construction of the castable depends on the rheological properties of the castable, which in turn depends on the particle grading of the castable (ie the ratio of aggregate to binder). At the same time, according to the process requirements of the cement kiln (including process temperature, dust content, etc.), the alkali resistance and wear resistance of the castable are improved.

The aggregate is mainly made of vermiculite, and the base material is alumina (а-Al2O3) micropowder, silica micropowder and pure calcium aluminate cement, and the amount of alumina micropowder is added. Increasing the alumina micropowder will greatly improve the high temperature strength and wear resistance of the castable, but the excessive addition of alumina powder will affect the construction performance of the castable, and will also have a negative impact on the alkali resistance and corrosion resistance of the castable. . Therefore, the amount of alumina fine powder added plays a crucial role in the overall performance of the castable.

After the vibrating castable, it is advisable to maintain the natural surface. It is not advisable to use a tool to smear or to smear the surface. After the completion of the construction, within 24 hours of the construction body, especially before the castable is hardened, it is strictly forbidden to move and knock and vibrate, otherwise cracks will occur to complete destruction. Since the production and process control of cement enterprises have their own characteristics, the development of high-performance wear-resistant and refractory castables is to improve the construction plan and ensure the construction quality, and to improve the tertiary air duct and the wind damper and the chiller throat. , kiln door cover and other parts of the refractory properties (ie strength and wear resistance, alkali resistance, corrosion resistance). The amount of pure calcium aluminate cement added. Adding an appropriate amount of pure calcium aluminate cement can improve the high temperature performance and low temperature strength of the castable. However, too much addition will affect the construction performance of the castable and shorten the hardening time of the castable. Therefore, the pure calcium aluminate cement in the castable must be in moderation. The amount of water added during construction.

The construction performance of the castable is not obtained by simply adding water. If the amount of water added is too much, the separation of the aggregate and the base material will occur, which will affect the performance of the castable, and will also reduce the density, strength, alkali resistance and wear resistance of the castable. Insufficient water addition, poor construction performance, material can not flow normally and reach dense filling, bubbles can not be discharged, can not form close packing, and will also affect the performance of castables. Therefore, controlling the amount of water added during the construction of the castable is very important for the performance of the castable.

Relevant Product Display

Refractory artesian castable

Refractory artesian castable

Medium temperature anti - corrosive spray paint PT-130

Medium temperature anti - corrosive spray paint PT-130

Vacuum forming abnormal products

Vacuum forming abnormal products

DL Series of light insulation refractory castable

DL Series of light insulation refractory castable

Relevant information

Hotline