Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Technical knowledge ->

But the plastic is by the powder and the powder material and plastic clay and so on binding agent and increases the plastic to cooperate, adds the small amount of water, through the full mixing, is composed of a kind of assumes the plaster shape and maintains the high plasticity in the longer time the amorphous refractory material.

Granular and powdery materials are the main components of plastics, generally accounting for 70% ~ 85% of the total.It can be composed of various refractory materials, and often according to the material can be classified and named plastic.Because this kind of amorphous refractory material is mainly used in the heating furnace which does not directly contact with the molten material, the clay clinker and high aluminum clinker are generally used.Lightweight plastics can be made of lightweight granular materials.

Plastic clay is the main component of plastic, although it accounts for 10% ~ 25% of the total amount of plastic, but it has a great impact on plastic plasticity, binding strength, volume stability and fire resistance of plastic and its hardening body.In a sense, the nature and quantity of clay can be considered to control the nature of plastic.

General requirement but plastic should have taller plasticity, and after be being stored for long time, still have certain plasticity, call but the working sex of plastic.Plasticity is related to the properties of clay and the amount of clay used. In addition, it is mainly dependent on the amount of water, which increases with the amount of water.However, too much water can have adverse effects.Generally 5% ~ 10% is appropriate.

To make plastic plasticity in its preservation period without significant reduction, can not use hydraulic binder.

But plastics do not require special technology in construction.When used to make furnace lining, take out the plastic from the sealed container, lay it between hanging bricks or pull hooks, and pound it with wood hammer or air hammer (each layer is 50mm ~ 70mm thick).The surface can be machined before hardening.In order to facilitate the discharge of moisture, open the pores at certain intervals.Finally, expansion and contraction joints are set according to the design.If it is used to make the whole furnace cover, it can be constructed on the bottom mold first, and then hoisted after drying.

Can plastic bottom use temperature basically USES quality of granular and powdery material bottom and different.For example, ordinary clay can be used for less than 1300℃ ~ 1400℃, and high quality clay can be used for 1400℃ ~ 1500℃.High alumina 1600℃ ~ 1700℃ or higher;Chrome quality 1500℃ ~ 1600℃.

Relevant Product Display

Alkali resistant refractory castable

Alkali resistant refractory castable

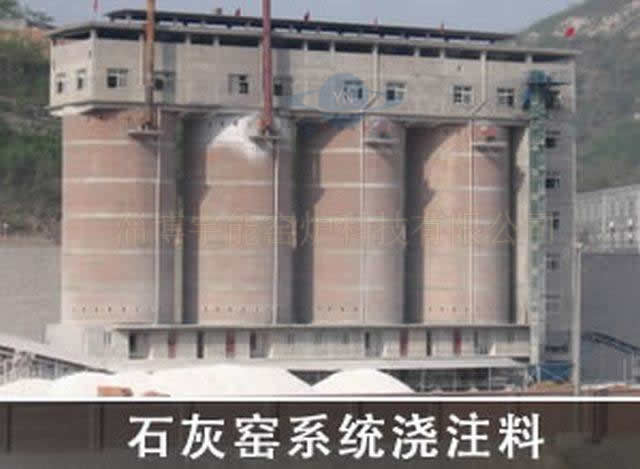

Lime kiln system castable

Lime kiln system castable

Refractory for ladle, heat preservation furnace, etc

Refractory for ladle, heat preservation furnace, etc

Slag resistant and abrasion resistant castable is slag free

Slag resistant and abrasion resistant castable is slag free

Relevant information

Hotline