Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

Wear-resistant castable is a new inorganic compound building material.It has simple construction, erosion resistance, high temperature resistance, thermal shock resistance and good group, easy to make up for other characteristics, and cheap price, convenient handling.

Basic performance

Compressive intensity ≥70MPa

Elastic modulus ≥4.0×104MPa

Wear is 1 kg/m2 or less

Temperature resistance ≤600℃

Parameters of 0.015 or less

Thickness ≥40 ~ 50mm

Function and usage

Share the scope

Suitable for wear - resistant layer in slag ditch and ore trough

1. Construction facilities and tools

Forced cement mixer, plate vibrator, polishing machine.

2. Construction preparation

(1) cement base dry treatment

A. Clear the basic surface without debris such as gravel and floating pulp.If the basic layer has loose parts, it should not be used.

B. For cement with a large vertical or inclined Angle, it should be placed in plum nails (6 ~ 8mm steel bar with a width of 30mm, a shape of y, and a spacing of 250mm between plum flower nails).

C. The basic surface shall be fully wetted for 2 hours.

(2) steel base dry treatment

A. Rust removal on the surface of steel, oil stains and other debris removal.

B. Place club nails (same as above).

(3) the mixer should be close to the construction coordinates as far as possible, which is conducive to the continuous development of the construction, the stirring water should be clean water, prohibit the use of sewage, waste water and water containing impurities.

3, stirring

Pour wear-resistant pouring material into the blender, start the blender, stir for 1 minute.

(2) pour the weighed water (7% ~ 9% water) into the blender and stir for 2 ~ 3 minutes.When falling agitator, the agitator time should be prolonged appropriately.Can collapse should be kept within 3±1mm.

4, construction

(1) construction begins, should remove the surface layer of residual water, with a brush will match good yx cement interface treatment agent average brush in the basic surface layer, before dry should immediately start pouring construction.

(2) put the wear-resistant pouring material into the template, citing the vibrator shock.Vibration for a while should be based on wear - resistant castable surface grouting.If the pouring layer is relatively thin and it is not convenient to use the vibrator to vibrate, you can use the method of wiping and pressing, but in the construction, you should pay attention to beating and compaction, until the skin regrouting, and finally carry out the compaction treatment.

(3) operational time: from add water stirring to the completion of pouring, early strong wear-resistant pouring material, the construction operation time should be controlled within half an hour, the construction operation time of conventional wear-resistant pouring material should be operated within one hour, do with stirring, with pouring, with vibration.

(4) maintenance: after the final setting of castable should be wet maintenance, maintenance method and maintenance time can be in accordance with the requirements of reinforced cement construction.

Relevant Product Display

Wear-resistant refractory castable D-14M

Wear-resistant refractory castable D-14M

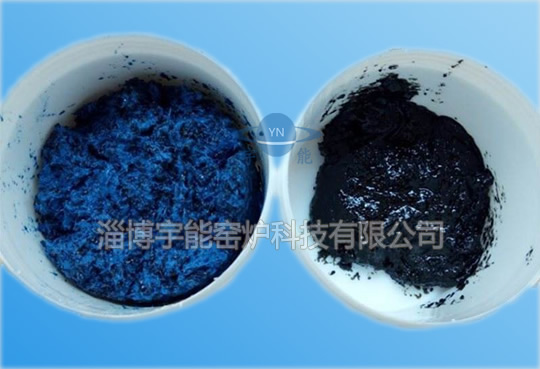

High strength and abrasion resistant plastics

High strength and abrasion resistant plastics

High wear resistance toughness ceramic coating TD-YMT

High wear resistance toughness ceramic coating TD-YMT

High aluminum and high strength castable G-16

High aluminum and high strength castable G-16

Relevant information

Hotline