Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

1. Add binding AIDS to adjust the hardening time

The fast hardening of castable is very important for the rapid demodulation after construction. By adding the binding agent to promote the hardening, it can ensure that the castable has enough construction time. Meanwhile, it must be hardened quickly after casting, so as to release the mold in time for baking.The hardening time of castable also has a great relationship with the swelling and bursting of castable.Too fast hardening and too slow hardening of castable will cause swelling and bursting of castable.Therefore, by adding an appropriate amount of binder, the hardening time of castable can be effectively controlled, and thus prevent the swelling and crack caused by gas generation.After pouring, the castable with aerating agent and binding aid can be baked immediately. It can be solidified and demodulated in about 1 hour. After solidification, the sample blocks can be directly placed in the 450℃ furnace without bursting.

2, add organic fiber to improve anti-bursting

From the relationship between the vapor pressure and temperature of water, it is not difficult to see that the vapor pressure rises rapidly when the water is over 100℃.When the casting body is baked, the water in the casting material will quickly vaporize due to heat.The main reason for the baking cracking and bursting of castable is that the rapidly formed steam cannot be discharged out of the pouring body in time and the pressure of steam inside the pouring body is too high.

Adding explosion-proof fiber is one of the most effective explosion-proof measures for castable.The principle of fiber explosion proof is that the fiber shrinks or decomposes rapidly after the castable is heated, and at the same time, the stomatal passage is formed in the castable, so that the steam generated by the castable is diffused and volatilized out quickly.The water vapor in the castable can be diffused out in time without gathering and forming greater pressure in the castable body, and the castable will not burst.However, there are many kinds of fibers, so it is very important to choose the varieties, diameters, lengths and quantities of castable for its explosion-proof effect.In this study, after reasonable selection and adding the appropriate variety and quantity of fiber into the castable, the poured samples were directly baked in a high-temperature furnace at 200℃, and the surface of the samples was intact without bursting.

3, add alkali emulsion explosion-proof agent

Alkali emulsion explosion-proof agent is a new type of explosion-proof agent which has been reported in recent years.Some literatures have introduced its explosion-proof mechanism as follows: when the castable is heated and dried, the dehydration and gelatinization of the alkali emulsion will form a net sheet microcrack channel in the matrix, thereby increasing the permeability of the castable.In addition, it is said that the alkali emulsion can inhibit or delay the formation of CAH10, and can also improve the bursting temperature of castable.In order to further improve the explosion-proof effect of castable, the application research of alkali emulsion explosion-proof agent was carried out. Through the dose-matching research, the anti-bursting temperature of castable was increased from the original safe explosion-proof temperature of 400℃ to 600℃, which made the quick-drying explosion-proof castable have safer performance.

4. Use efficient water reducer

The burst of castable is mainly caused by the steam generated after the water is vaporized by heat and cannot be discharged out of the castable body in time. Therefore, it is a necessary way to reduce the amount of added water of castable.The traditional water-reducing agent of castable mainly USES sodium tripolyphosphate or sodium hexametaphosphate in combination, but for castable containing C quality, the added water amount generally reaches more than 6%.Later, we adopted high-efficiency water-reducing agent to achieve better dispersing effect. The addition of water volume was controlled at about 5%, which was 20% lower than that of sodium tripolyphosphate and sodium hextaphosphate.

Through the above methods, the castable is modified to effectively solve the problem of fast dry demodulation, fast baking and blowout prevention of castable in the iron groove of large blast furnace, which is applied to the overall casting of small and medium-sized blast furnace with single iron mouth, and obtains very satisfactory results.

Relevant Product Display

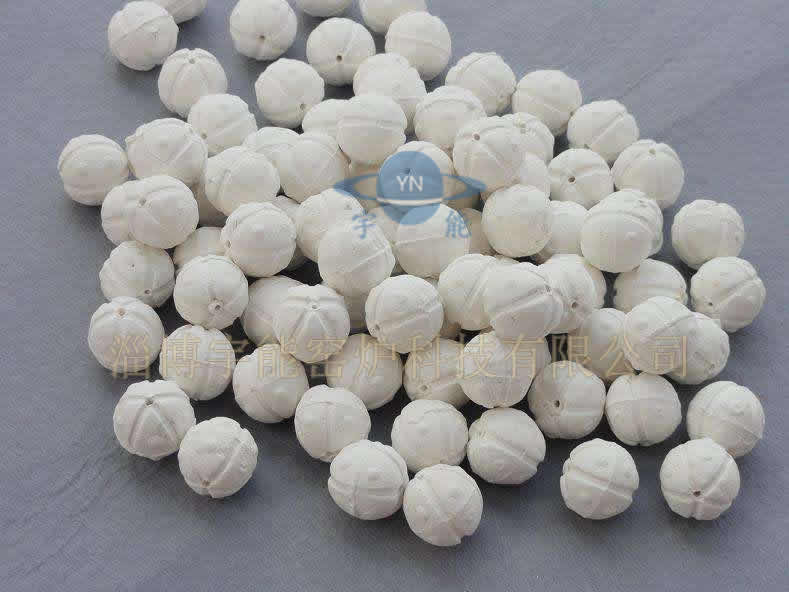

High aluminum wear-resisting ball

High aluminum wear-resisting ball

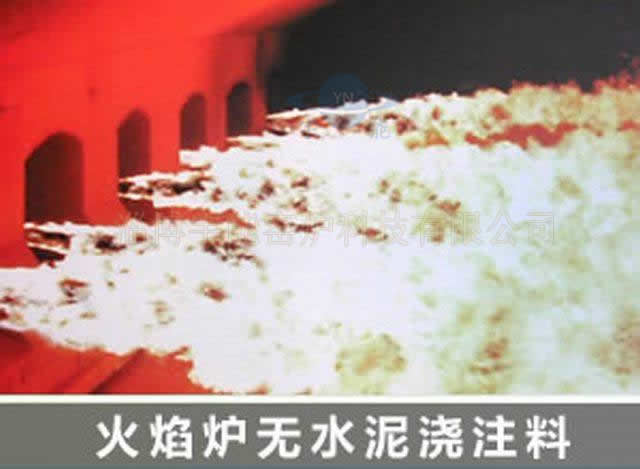

Castable for flame furnace systems

Castable for flame furnace systems

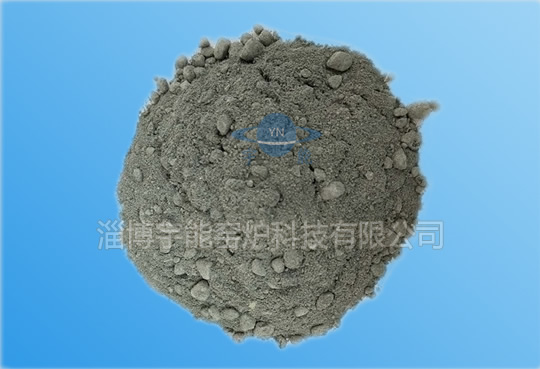

High wear and erosion resistant castable G-17M

High wear and erosion resistant castable G-17M

High strength refractory castable D-16

High strength refractory castable D-16

Relevant information

Hotline